Crushing and Sieving Laboratory

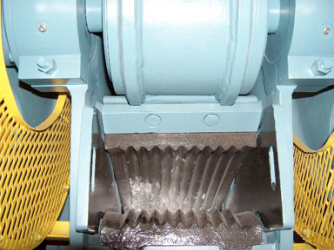

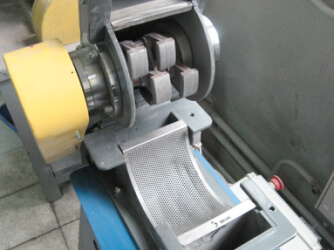

Research activities are conducted with a view to determining the physical and mechanical properties of raw materials and the appropriate selection of machines and their design and operating parameters, as well as technological systems to optimise the crushing, grinding and sieving processes.In the laboratory, it is possible to obtain mineral aggregates of the required grain composition and shape in innovative patented installations, as well as to prepare raw materials for subsequent processing in unique machines, e.g. gravitational enrichment, magnetic enrichment, flotation, hydraulic classification, or to prepare powder samples for chemical or mineralogical analyses.With the help of selected equipment in the laboratory, it is possible to simulate technological systems of crushing, grinding (assessment of energy intensity) and screening processes of mineral raw materials for industrial conditions.The laboratory facilities include: crushers (jaw, roller, impact hammer, cone, shredder), mixers (ball, rod, planetary, Bond), high-pressure roller press HPGR, pressure roll-matrix agglomerator, multi-deck sifters for wet and dry operation, three-deck six-product sifter for production of shaped and unshaped aggregates, and shakers with analytical sieves.

Contact details for the laboratory manager/supervisor:

Dr hab. inż. Tomasz Gawenda,

prof. AGH (kierownik lab.)

gawenda@agh.edu.pl

692318800 / 126174559

Scientific areas the staff are specialised in:

- Evaluation of selected physical and mechanical properties of raw materials and waste (analysis of grain size and shape of FI and SI shredding products, density, absorbability)

- Assessment of the influence of the type of shredding and sieving machines and their design and operating parameters on the efficiency of the shredding and sieving process.

- Adjustment.